|

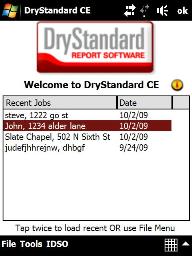

The DryStandard™ Software is brilliantly assembled with easy to use and intuitive for novice

computer users. A simple welcome screen lists recent jobs that can be opened on the cell phone

or quickly updated by logging in to the IDSO server to retrieve the latest project readings.

The DryStandard™ Software is brilliantly assembled with easy to use and intuitive for novice

computer users. A simple welcome screen lists recent jobs that can be opened on the cell phone

or quickly updated by logging in to the IDSO server to retrieve the latest project readings.

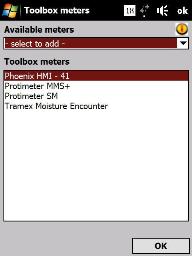

Toolbox (meters): Only the meters, that are in your inventory will be prompted for the technician’s choices. Further, when collecting the meter readings, if the meters are not designed for use on the substrate being tested... they will not be offered to the technician. This compels the responsible use of meters from the technicians. Further, all meter corrections are programmed into the software to adjust for the substrate temperature and wood species. This makes the challenge of responsible meter use a snap, and painless. These corrections are included not only in the final report – but also right on the cell phone screen!

Toolbox (meters): Only the meters, that are in your inventory will be prompted for the technician’s choices. Further, when collecting the meter readings, if the meters are not designed for use on the substrate being tested... they will not be offered to the technician. This compels the responsible use of meters from the technicians. Further, all meter corrections are programmed into the software to adjust for the substrate temperature and wood species. This makes the challenge of responsible meter use a snap, and painless. These corrections are included not only in the final report – but also right on the cell phone screen!

The user has the option of collecting either Metric or Imperial measurements – and can even be swapped / converted in the middle of a job.

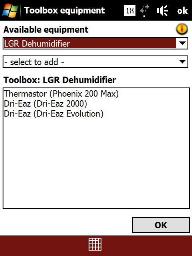

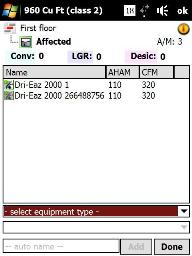

Toolbox (drying equipment): Only the dehumidifiers, furnaces, A/C units (etc) that are in your inventory will be prompted for the technician’s choices. This list possesses all the specifications of the equipment in the background, including cfm, compressor btu, furnace btu, Amps, Volts, Phase... all specifications that may be used to instantly evaluate and report the machine’s performance to the technician – instantly. When the machine’s expected performance drops below a certain threshold, the user is prompted to remove / replace this unit.

Toolbox (drying equipment): Only the dehumidifiers, furnaces, A/C units (etc) that are in your inventory will be prompted for the technician’s choices. This list possesses all the specifications of the equipment in the background, including cfm, compressor btu, furnace btu, Amps, Volts, Phase... all specifications that may be used to instantly evaluate and report the machine’s performance to the technician – instantly. When the machine’s expected performance drops below a certain threshold, the user is prompted to remove / replace this unit.

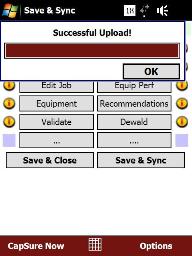

Home Screen: Simple choices to guide the technician in editing / reviewing the projects readings.

Home Screen: Simple choices to guide the technician in editing / reviewing the projects readings.

The Fast Track button is a highlight of the program. After the first day’s readings have been entered, each subsequent day's readings only require the technician to simply hit the fast track button – and the technician will be prompted to enter ONLY the data that requires readings. Inspections sites, rooms and chambers that are acceptably dry will not be prompted for additional readings – after all... they are acceptably dry! This makes daily readings absolutely as efficient as possible.

Each of the yellow “i” buttons on the screen are the user’s resource if they have any questions about what each button does. You just can’t get lost in here.

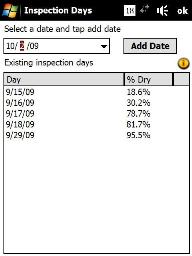

Calendar: A drop down calendar makes adding dates easy if an inspection day has been missed.

Calendar: A drop down calendar makes adding dates easy if an inspection day has been missed.

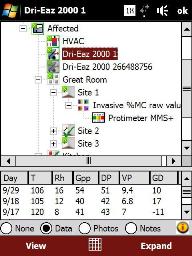

The “Edit Job” button: Stay Organized!: All environments, Drying Chambers, Rooms (in the chambers), Equipment, Inspection Sites, Meter Choices, Inspection Types (invasive, non invasive etc) are kept in logical and predictable order. (the order of each node can be moved if desired by “tap and hold” on the node to be moved.) A series of other options are available with the tap and hold feature on any of the nodes in the hierarchy.

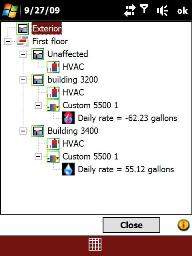

A green check mark on the icon means the site is acceptably dry! You know in an instant what remains to be dried.

A green check mark on the icon means the site is acceptably dry! You know in an instant what remains to be dried.

A small green box in the top left corner of the icon means there are photos associated with that node!

When one of the icons is "grayed out" (notice the second dehumidifier in the hierarchy), that means the dehumidifier has been removed from the project but the readings are still recorded for the report.

The “expand” button on the bottom right corner of the screen allows the user to expand / collapse the hierarchy to whatever level they wish with a click of the button. (Valuable on LARGE jobs.)

Environmental and Dehumidifier Data: Do you have difficulty collecting all the necessary readings to complete the drying records? DryStandard software records not only the moisture meter readings – but also all the drying equipment data necessary to prove the forces produced by your drying strategy. Each device that has the potential to remove (or add) water is prompted for data collection. This is reported on this same hierarchical screen. Note: “gallons or pints per day” are not listed here. That’s a different button: Equipment Perf.

Environmental and Dehumidifier Data: Do you have difficulty collecting all the necessary readings to complete the drying records? DryStandard software records not only the moisture meter readings – but also all the drying equipment data necessary to prove the forces produced by your drying strategy. Each device that has the potential to remove (or add) water is prompted for data collection. This is reported on this same hierarchical screen. Note: “gallons or pints per day” are not listed here. That’s a different button: Equipment Perf.

Note: DryStandard Software actually corrects “cubic feet per pound of air” in calculating the grain depression from these drying systems. Accuracy is the name of the game.

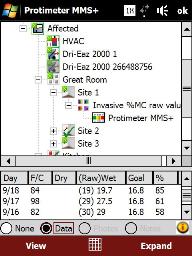

Inspection site details: Each inspection site has the complete history to the drying logs collected and displayed to the user. In this image the temperature of the material and species of wood has been used to correctly (and responsibly) change the meter reading for the technician (See top line dated 9/18: The meter reading displayed numeric value of 19 – but this is really a 19.7). The drying goal is also listed for the technician based on industry accepted practices. This is driven down to a simple statement of “percent to completion”. In this case the site is 85% to completion.

Inspection site details: Each inspection site has the complete history to the drying logs collected and displayed to the user. In this image the temperature of the material and species of wood has been used to correctly (and responsibly) change the meter reading for the technician (See top line dated 9/18: The meter reading displayed numeric value of 19 – but this is really a 19.7). The drying goal is also listed for the technician based on industry accepted practices. This is driven down to a simple statement of “percent to completion”. In this case the site is 85% to completion.

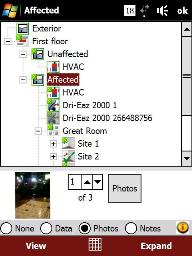

PAPERLESSNESS! (This was a primary goal in the creation of the software – and we have succeeded!) The challenge was to figure out how to “map” the inspection sites without paper – and without an internet connection. It took us 5 years to develop... but we made it! The answer was in using the cell phone’s camera. Simply click the node (any of the nodes in the hierarchy!!) and then click the photo button in the DryStandard Software. The program fires up the camera, take the picture, and that photo is now resized in the program and automatically inserted in the formal DryStandard Report. Simple, easy and FAST.

PAPERLESSNESS! (This was a primary goal in the creation of the software – and we have succeeded!) The challenge was to figure out how to “map” the inspection sites without paper – and without an internet connection. It took us 5 years to develop... but we made it! The answer was in using the cell phone’s camera. Simply click the node (any of the nodes in the hierarchy!!) and then click the photo button in the DryStandard Software. The program fires up the camera, take the picture, and that photo is now resized in the program and automatically inserted in the formal DryStandard Report. Simple, easy and FAST.

Now... how easy was THAT?! You can take as many photos as you like on any node in the hierarchy and they will all be included in the correct locations in the final report.

Simply place a small IDSO colored and numbered sticker onto the site being inspected... photograph the inspection site and the record can be recalled at any time by future technicians.

Equipment Calculations: Love them or hate them... The restoration industry’s current dehumidification formulas are responsibly expressed as a “suggested dehumidification formula for STARTING a job.” This starting recommendation is included in the software. But ask anyone how you use the formulas if you are going to mix the drying technologies (conventional, LGR and desiccant) and you will get a variety of puzzled looks or opinions. Note: DryStandard Software allows the technician to MIX dehumidification technologies while complying with the IICRC formula and not overloading the project. You can actually mix all three technologies and the correct amount will be recommended.

Equipment Calculations: Love them or hate them... The restoration industry’s current dehumidification formulas are responsibly expressed as a “suggested dehumidification formula for STARTING a job.” This starting recommendation is included in the software. But ask anyone how you use the formulas if you are going to mix the drying technologies (conventional, LGR and desiccant) and you will get a variety of puzzled looks or opinions. Note: DryStandard Software allows the technician to MIX dehumidification technologies while complying with the IICRC formula and not overloading the project. You can actually mix all three technologies and the correct amount will be recommended.

The other real difficulty is determining if the dehumidification needs are sufficiently assisting the drying process. That’s where DryStandard Software really shines. DryStandard Software measures the influence of the drying strategy on the materials to be dried. This is actually derived from an extrapolated calculation of the vapor pressure in the hygroscopic materials being dried and the vapor pressure in the environment. Thank goodness for computers!

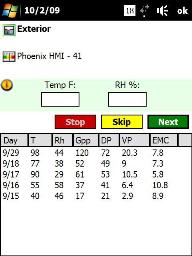

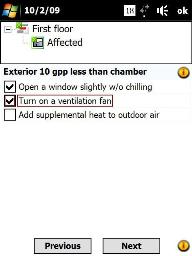

Fast Track Screen: On day 2 and 3 and 4... open the job and hit the Fast Track button.

Fast Track Screen: On day 2 and 3 and 4... open the job and hit the Fast Track button.

You are presented with a simple question the gets you right to the point... Just answer the question on the screen!...

What is the exterior temperature and relative humidity? (enter the data)

Hit the next button... and the software will ask the next relevant question!

Repeat...

...How fast is that?!

In a few minutes you are done with your data collection and it is all organized and evaluated. Wait until you see what it does next!....

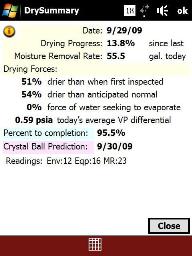

No More ARGUMENTS!: GPP?... relative humidity?... temperature?... beeping meters?... Will someone please tell us how this job is progressing! Give it to me straight!

No More ARGUMENTS!: GPP?... relative humidity?... temperature?... beeping meters?... Will someone please tell us how this job is progressing! Give it to me straight!

This screen drives the meter readings down to the simplest of statements that anyone with an elementary school education can understand.

Think of the value of this kind of summary to the insurance adjuster that is baffled or confused with your drying documents. It’s about time we produced something like this. This screen... this summary... will change the restoration industry.

Let’s start answering the REAL questions on the minds of the consumers.

Consider the value of this kind of summary when you encounter those that would challenge your drying strategy. It would sure be nice to have a statement of fact related to the forces incurred on your drying project.

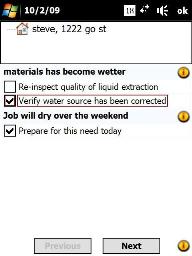

Recommendations!: Are you sick and tired of people who want to “arm chair quarterback” your drying process and tell you how you did it wrong? Where were they when you were actually doing the job? You would think that in today’s day and age, software could actually perform complex analytics that will produce powerful and effective recommendations to assist and guide the restorer in delivering a responsible drying strategy... instantly!

Recommendations!: Are you sick and tired of people who want to “arm chair quarterback” your drying process and tell you how you did it wrong? Where were they when you were actually doing the job? You would think that in today’s day and age, software could actually perform complex analytics that will produce powerful and effective recommendations to assist and guide the restorer in delivering a responsible drying strategy... instantly!

Well – it’s finally here!

Responsible documentation is not just about data collection. It is about converting the data into drying decisions that count, and work! These recommendations and thresholds are currently produced from IICRC recommendations and theory. More complex evaluations will become available soon (notice the blank buttons on the home screen). Let’s see what the “arm chair quarterbacks” do with THIS information!

Responsible documentation is not just about data collection. It is about converting the data into drying decisions that count, and work! These recommendations and thresholds are currently produced from IICRC recommendations and theory. More complex evaluations will become available soon (notice the blank buttons on the home screen). Let’s see what the “arm chair quarterbacks” do with THIS information!

Important: DryStandard software does not impose the recommendations upon the technician. The technician shall always be in ultimate control of the project and the drying choices made. With this in mind, the technician has the option to execute the recommendations... or ignore the recommendations. No problem! The restorer shall always have control. The ones that he DOES choose to employ are “checked” and remembered and reported in the final DryStandard Report, and daily electronic email summary sent to the interested parties to the project.

Isn't that the way it SHOULD BE?! You are the professional on the job. DryStandard Software is a tool that enables the restorer to correctly calculate psychrometrically complex drying decisions INSTANTLY on the job. Every single drying technician in your staff can now be true Drying Deities supported with the finest documentation available... all from their cell phones!

Drying Equipment Performance: It’s not just about “gallons per day”. It is about the machine’s performance related to what it is expected to deliver. The software does these analytics (and more analytics are coming soon). Notice how there is a big red question mark on the desiccant dehumidifier 5500 – 1 whose readings suggest that it is ADDING 62.23 gallons of water to the environment per day. This is clearly a faulty reading. You can see at a glance if your readings appear faulty and require attention. HVAC systems, furnaces and air conditioners are also evaluated for moisture removal performance.

Drying Equipment Performance: It’s not just about “gallons per day”. It is about the machine’s performance related to what it is expected to deliver. The software does these analytics (and more analytics are coming soon). Notice how there is a big red question mark on the desiccant dehumidifier 5500 – 1 whose readings suggest that it is ADDING 62.23 gallons of water to the environment per day. This is clearly a faulty reading. You can see at a glance if your readings appear faulty and require attention. HVAC systems, furnaces and air conditioners are also evaluated for moisture removal performance.

Sync with the IDSO Server: Every day that the technician collects readings, he simply clicks the “save and sync” button, and the cell phone will briefly connect to the internet, and send the data to the servers. (No special set up is required!).

Sync with the IDSO Server: Every day that the technician collects readings, he simply clicks the “save and sync” button, and the cell phone will briefly connect to the internet, and send the data to the servers. (No special set up is required!).

No office administration needed. No redrawing the moisture maps at the office. No data entry into Excel spreadsheets. No live internet connection required for tedious data entry. Once the technician enters the data on the cell phone, the task is done and the report is perfect – complete with analytics.

Once the servers receive this data, an html email is created that reports a very brief summary about the job and sends this email to those in the email list associated with that job. Finally, for those that want the nitty gritty details, a technical, fully documented college level DryStandard Report is also generated and included on the bottom of every email. There is no limit to how many reports the user can produce. Document all the projects you like!

|